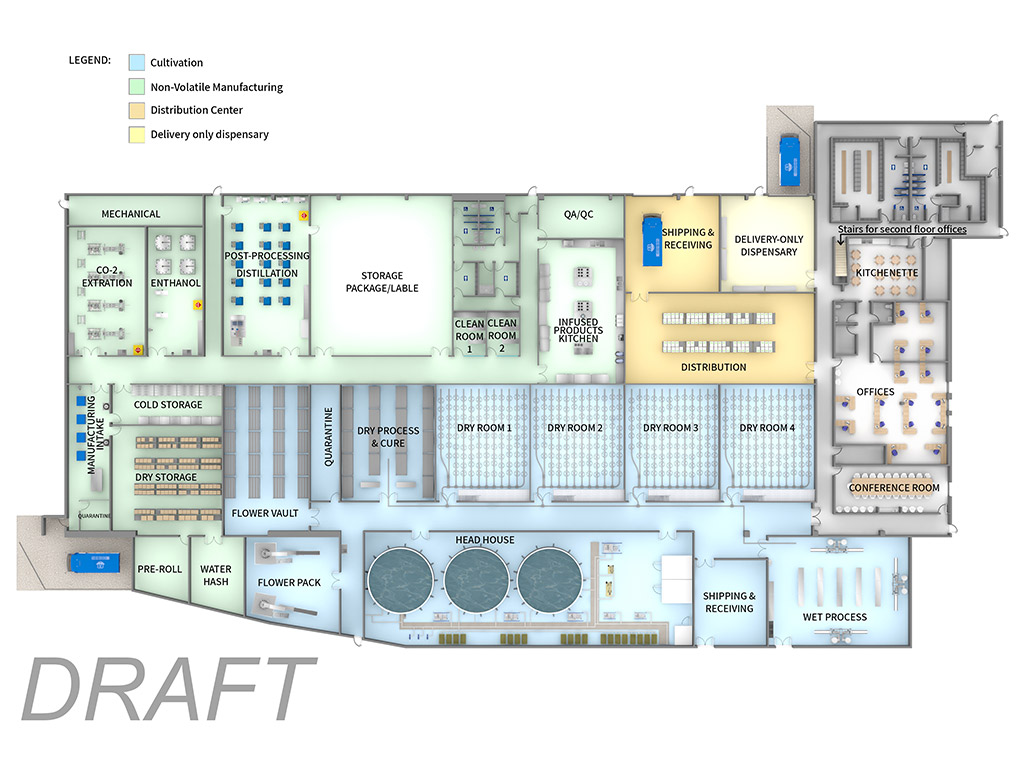

You must develop a business plan, determine your budget, and secure funding before completing a license application. Most importantly, you’ll need to research your state’s cannabis laws and license application requirements.

We understand that learning the industry can be a daunting task, so we offer license procurement services.

With our comprehensive knowledge of the cannabis industry application process, we have won and secured operational licenses in competitive markets from PA, MD, OH, CO, AK, VA, CA, and NV.