Cannabis genetics are the backbone of commercial cultivation success. No matter how much you invest in cutting-edge facility design, equipment or labor, your true source of potential lies in the qualities of the plants themselves.

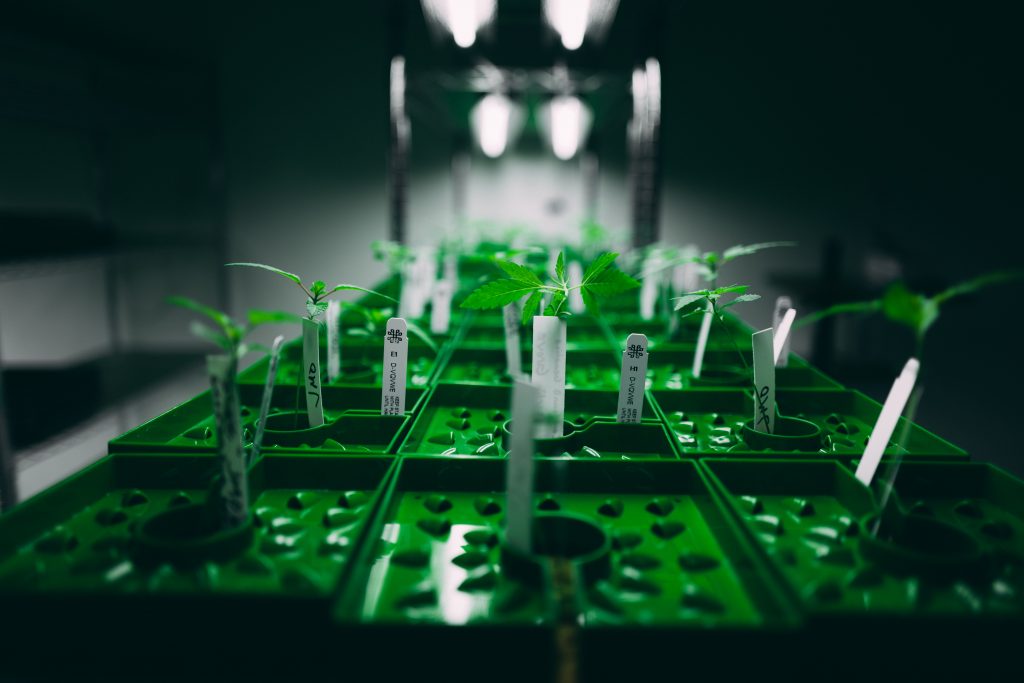

Building a diverse cannabis strain library that balances consumers’ demand for novelty with the actual logistics of growing cannabis at scale is crucial. Whether you’re focused on producing flower for retail sale, biomass for extraction, developing phenotypes of your own or a mix, it’s key to be strategic about maintaining a roster of cannabis mother plants for cloning and establishing a production schedule that meets all of your needs.

Here’s essential info about the rise of cannabis genetics knowledge, and the business implications for cultivators operating in established and emerging markets:

Cannabis Genetics History and Evolution

In the legal era, cannabis genetics has grown into a robust sector that combines elements of agriculture and biotech, and what agronomists and scientists continue to learn about cannabis pushes the industry forward every day.

From classic strains like Acapulco Gold, Durban Poison and G13, to trendy offerings like Rainbow Belts, Garlic Breath and Kush Mints, cannabis breeders have created a wider variety of cultivars than ever with a dazzling array of characteristics. But how did we get here?

Origins of the Cannabis Species

The species Cannabis Sativa L., like many domesticated crops, has evolved over thousands of years from a wild plant to one carefully cultivated for specific characteristics. While there are a number of theories about cannabis origins, recent research suggests East Asia is the birthplace of cultivated cannabis.

Around 12,000 years ago in what is now northwestern China, humans began growing cannabis plants for fiber and food. From East Asia, cannabis spread across Central Asia and throughout the rest of the world. As cannabis made its way to new continents such as Africa and the Americas, it adapted to the regional climate and its growth habits became distinct, from bushy indicas to lanky sativas.

Cannabis was also cultivated for medical and spiritual purposes in addition to its utility for fiber and seed oil, with many unique traits, or phenotypes, isolated and later crossbred to create new cultivars. Today, there are countless cannabis cultivars that vary from industrial hemp low in THC, to strains rich in a full spectrum of cannabinoids.

What are Cannabis Phenotypes?

Simply put, phenotypes are the outward expression of a cannabis plant’s genetics as influenced by the plant’s growing environment.

Millennia ago, Neolithic farmers were the world’s first phenohunters—growers who seek out cannabis varieties with specific characteristics and breed them over time to produce stable, predictable strains. Some of the legendary cannabis strains on today’s market hint at their ancient geographic origins, from Hindu Kush to Thai to Afghani.

Today’s phenohunters are able to take a far more granular approach to cannabis genetics than the growers of yore, isolating and enhancing concentrations of different cannabinoids such as cannabigerol (CBG), tetrahydrocannabivarin (THCV) cannabinol (CBN), cannabichromene (CBC) and dozens of others—not to mention the cannabis terpenes that are the focus of many extracts and concentrates on the market.

How Cannabis Genetics Factor Into Commercial Production

Cultivators can certainly use the knowledge base of cannabis genetics to focus on cannabinoid and terpene profiles associated with certain effects and potencies. But an understanding of cannabis genetics is also important for the day-to-day challenges of large-scale cannabis production.

Cannabis genetics is something of a two-fold field: On the one hand, cultivators continue to produce well-known, classic strains that don’t deviate from their famous flavor and effects profiles while maintaining robust plant health over many generations of seeds and clones. On the other hand, breeders are also working to create novel exotic strains that meet the market demand for buzzworthy exclusiveness and enhance our knowledge of what this plant can do.

In a facility’s production schedule, plant genetics also factor into the size and shape of the plant itself, how quickly it develops, the physical structure and visual appearance of its buds and trichomes, how well the plant can resist pests and pathogens such as mold and diseases, and how much water, light and nutrients the plant needs to thrive.

Commercial cultivators can use their knowledge of genetics to identify which strains will be best to grow from a retail perspective, and more critically, to set up an efficient workflow by growing certain strains together in “management groups,” as we call them at Next Big Crop.

Management groups consist of cultivars that grow well together, with similar traits and irrigation requirements. This approach simplifies logistics for the cultivation team throughout the production cycle and boosts the “speed to jar” factor.

Phenohunting and Experimentation

There can be a lot of phenotype variability even within a single genetic strain. For example, when comparing two samples of Kush Mints flower sourced from wholesalers in two different states, one might find variations in the scent, appearance and taste of each depending on their mother plants, how each was cultivated and how the harvest was cured and packaged.

Therefore, phenohunting isn’t just a matter of discovering exciting new strains. It’s also common for cannabis breeders to seek out the best possible iteration of popular strains to optimize production. It’s an exercise in patience and persistence.

Planting from seed with phenotypes in mind can look like systematically growing 10 plants from seeds and waiting to see which provides the best yield, the right size and the right balance of smell, taste, potency and plant size. A cultivator might luck out and find that, say, seed #4 out of 10 was the Goldilocks plant that meets all the right phenotype criteria. They also might not, requiring further experiments that extend the grow timeline before sale.

Cannabis Clones Vs. Seeds

There are key differences between using cannabis clones versus seeds in production. Each propagation method serves a purpose and has pros and cons depending on whether you’re phenohunting, establishing a clone nursery, trying to start a commercial cultivation operation in a restrictive market or refresh an established strain library, among other goals.

One consideration for new operators is the time factor: Starting a grow operation from seeds alone can be a longer play than some cultivators are comfortable with. It takes time to identify and establish mother plants, in order to produce a significant number of clones for a uniform crop.Quality is also a key concern. When you’re popping seeds, the consistency just isn’t there.

If you plant 100 regular seeds of any particular strain, you’re going to get 100 phenotypically different plants—some nice plants, some ugly plants, big ones, small ones, some males, plants that smell great, plants that smell like hay. But if you cut 100 clones from a single mother plant for the production cycle, you’re going to have identical genetics and consistent results.

Another complication for growers starting with seeds are the differing characteristics of regular, feminized or autoflower seeds, and the impact on lighting schedules.

Regular seeds can produce a mix of male and female plants, meaning extra care needs to be taken to avoid undesired seed production. In comparison, seed companies sell feminized seeds with a claim they produce female plants 99.9% of the time. For both regular and feminized seeds, plants typically take 15-20 weeks from seed to harvest, and the flowering cycle is triggered by altering the photoperiod to 12 hours of light and 12 hours of darkness.

Plants grown with autoflowering seeds aren’t affected by the photoperiod and instead begin their flower production based solely on their age, usually at two to four weeks after germination, with harvest in about three months. The upshot with autoflower plants is that they have a speedier timeline to harvest, but typically a lower yield.

Strategies for Building Strain Libraries

A strain library encapsulates a commercial cannabis company’s approach to genetics and phenotypes, and it can look a lot different depending on whether the business is a cultivation wholesaler, seed breeder or vertically integrated company that does it all—growing, processing and retailing.

Just as a public library differs from an academic library, cannabis strain libraries can run the gamut from online databases stocked with digital genetics profiles to physical collections of curated strains organized in various ways, from landrace-based to new exotics to effects-focused groupings.

Building a strong strain library means not only determining which cultivars you want to have in your rotation, but how many plants of each variety you’ll need and where to source the best mothers for optimal phenotype expression across crops.

How Many Cannabis Clones Should I Start With?

Seeds may be a cheaper option at the outset, but the fastest and most efficient way to bring top-tier product to market is to source a production batch of clones, be it hundreds or thousands of seedlings.

Yes, it’s an expensive proposition, but it’s one that most quickly generates cash flow. And the ROI further comes from establishing a foundational strain library and giving the facility manager the ability to focus on dialing in operations and maximizing the production schedule from the get-go.

Making an investment in the right number of the right clones quickly pays for itself. Instead of spending months popping seeds to produce specific results to build a strain library, growers can work with strain specialists to reach that same end position by identifying top-performing clones and turning them into mothers. And with the right clones and group management, a cultivation team can harvest a full room of in-demand strains proven to turn a profit, all in about three months.

Tips for Establishing a Winning Strain Library

Whether you’re a big-budget MSO or a craft cultivation startup eager to establish a reputation for quality, these guiding principles for strain libraries hold true:

- Compatible logistics: Five great strains are better than a huge library with only two or three great varietals. Not only is it impractical to store and maintain plants that aren’t pulling their weight, having too many strains with widely variable growth requirements makes for inefficient production and runs up overhead costs.

- Consult sales staff: A good strain library doesn’t just serve the cultivators’ interests, it should also be built with input from sales staff. Because the lead time on releasing a new strain product is months at a minimum, you want to know ahead of time when to slot a new varietal into your production schedule and when to replace the previous “flavor of the month.”

- Seek quality sources: It can be frustrating and stressful to be ready to fill your vegetation room or restock your strain library only to, say, receive a damaged mother plant that needs weeks to be nursed back to health or receive a shipment of clones of different sizes and stages of development. Vetting the source of your clones and seeds can save a lot of time and money in the long run.

- Blend tried-and-true with up-and-coming: As you develop your library you need to find the balance between the MVP strains that everyone wants to stock up on and opportunities in your grow calendar to work in new strains of equal quality that will delight established and new customers alike.

- Don’t bother with B+ strains: Everything in your library should be Grade A. Remember, this is where your business potential is rooted. Don’t waste precious time, space or money on strains that yield poorly or are unpopular with consumers.

- Space constraints: While mother plants are essential to any cultivation operation, they have unique requirements for care. It can be tricky to find the right workflow balance between smaller plants that are easy to move through the production pipeline versus tending various-sized plants with varying growth preferences in a single room. A typical mother room may have a group of plus-size plants that are about to get cut off into clones and smaller “teenagers” coming up behind them from a different genetic group that the sales team is relying on to entice customers looking for variety.

- Be realistic about your timeline and budget: Any move you make in cultivation requires advanced planning with a typical lead time of at least three months. Growers must wait for a mother plant to reach sufficient size for cloning. The clones themselves will take two weeks to root. So while it may be faster to cultivate cannabis clones than pop seeds there are still trade offs, particularly when it comes to setting a budget. At best it can take six months to start a grow from one or two good clones. At worst, you might order hundreds of lackluster clones that don’t ultimately meet the needs of cultivators or sales staff.

- Prioritize a data-based approach: At Next Big Crop, time and again we’ve seen cultivation managers grappling with underperforming production schedules. To get on track, we ask our clients to take a step back: Consider your best-performing strain for a moment—the one with the highest yield and best potency that is in high demand and always flies off the shelf.

Now imagine if every plant in your facility performed that well. It’s amazing how both yields and sales can increase by 30% to 50% simply by removing underperforming or finicky strains from your library. Taking a data-based approach to cultivation is critical for maximizing your facility’s potential.

Get Cannabis Genetics Support

If this sounds like a lot to consider on top of all the other aspects of running a cannabis business, don’t worry. Cannabis genetics consultancies are increasingly popular resources to help a commercial cultivation business finetune its approach to breeding, strain selection and phenohunting.

Cannabis companies of all sizes benefit greatly from experienced support in sourcing top-quality genetics, developing a strain library and production rotation, along with identifying trends to consistently release exotic strains that aren’t found anywhere else.

Next Big Crop’s experienced team can help your business raise the bar on brand awareness, hit yield targets and improve sales metrics.

Next Big Crop cultivation specialists have advised business owners and investors in markets throughout America. We specialize in optimizing and scaling cultivation operations, with comprehensive support for cannabis genetics sourcing, license procurement, facility design and construction, as well as finer points such as system integrations, equipment and materials sourcing, facility management and compliance. Contact us today to expand your business.