When it comes to cannabis cultivation, innovation and refinement are the names of the game—and tissue culture technology is one of the best ways to play. Every grower wants to maximize their limited cultivation space, and mother rooms can take up more real estate than many realize. That footprint eats up budget as well as square footage.

With a smart tissue culture program, however, growers can prioritize genetic preservation, disease prevention and strain rotation while saving room both in the grow and on your business’s balance sheet.

Seamlessly integrating tissue culture into an existing operation is easier said than done, however. It takes real finesse to receive and acclimate cannabis tissue culture plants to ensure optimal growth and an easy transition.

Navigating the Nuances Between Tissue Culture Plants and Cannabis Clones

Tissue culture plants and traditional cannabis clones are both great options for commercial cultivators, but they offer distinct advantages that cater to specific needs and preferences:

| Tissue Culture Plant Advantages | Cannabis Clones Advantages |

| Tissue culture plants are pathogen free | Faster propagation to harvest cycle |

| Tissue culture mothers require less space | Replicable phenotypes without phenohunting |

| Genetic preservation | Affordable even for budget commercial cultivators |

| Ability to diversify strain library | Low technical barrier to entry |

Before you commit to a tissue culture operation, however, it’s important to take a realistic look at what’s required. Tissue culture plants have fewer vulnerabilities to pests and diseases than cannabis clones, but they also require a sterile lab—which in turn requires an upfront investment.

Cannabis clones, on the other hand, offer commercial cultivators a familiar growing process with little technical knowledge or additional equipment to acquire. But anyone who has been in a garden for a decade or two understands that cannabis clones tend to decline in performance over time.

| Tissue Culture Plant Disadvantages | Cannabis Clones Disadvantages |

| Tissue culture lab startup costs | Susceptibility to disease |

| Technical knowledge and training required | Limited genetic diversity |

| Sterile conditions required | Greater square footage required |

| Longer lead time | Declining quality over time |

How to Blend Tissue Culture Plants and Cannabis Clones in a Commercial Garden

How can growers get the best of both tissue culture plants and cannabis clones? A blended variety of clones/mothers/plant stock might be the best and fastest first step for your garden.

One method is to replace the mother stock in your garden every six months with tissue culture stock. This gives you a runway to establish a tissue culture lab while cultivation staff continue to take traditional cuttings to fill your grow rooms without interrupting your grow and harvest cycle. The reduced stress on your existing mother plants also helps protect them from the spread of pathogens and decreases the rate of quality decline.

Growing Cannabis Mothers from Tissue Culture

If setting up a tissue culture lab in-house at your grow isn’t feasible—or if you want to give your staff time to get up to speed on tissue culture propagation techniques—you might try sourcing tissue culture mothers. You’ll get the same strains with new vigor, and mitigate the risk of old, worn-out genetics that are more susceptible to pests and diseases. Think about it like leasing a car rather than purchasing one—you pay a little more, but you can avoid a lot of headaches down the road.

How to Receive Tissue Culture Plants

If you do opt to source genetics by way of tissue culture, you’ll want to make sure your facility is prepared for these especially fragile and susceptible plantlets. Similarly to receiving cuttings or rooted clones, you’ll want to establish a detailed standard operating procedure for receiving, isolating and integrating your new strains.

Upon arrival, meticulous inspection of your tissue culture plants is paramount. Carefully examine the packaging for any signs of damage or contamination. Vigilance at this stage sets the tone for the plant’s journey. No matter where you source genetics, we always recommend testing each variety for Hop Latent Viroid prior to integrating the new plants. This extra step could save you from unknowingly introducing HLV into your garden.

To prevent cross-contamination while waiting on a clean bill of health from the laboratory, quarantine the tissue culture plants in a separate area. This allows for close monitoring, minimizing the risk of spreading disease or pests to your existing crops. Sterilize all tools and equipment before handling the plants. This precautionary step mitigates the chance of introducing contaminants, ensuring a clean environment for your delicate specimens.

How to Acclimate Your Tissue Culture Plants

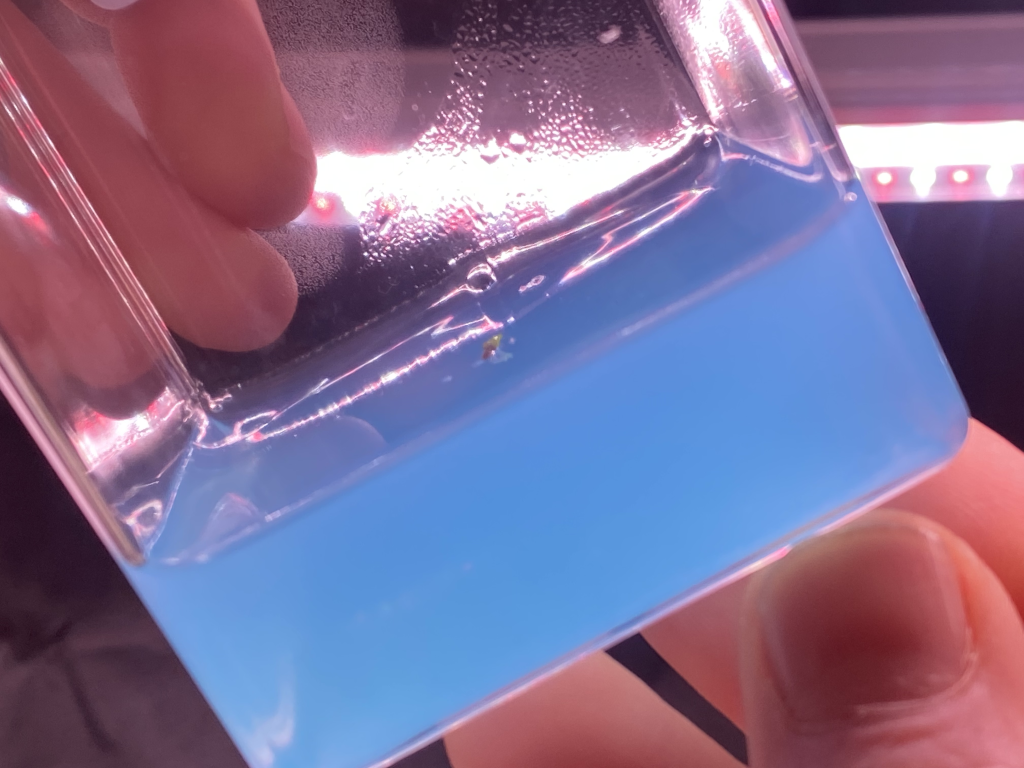

Prepare your growing environment with precision. From temperature to humidity, every factor must be fine-tuned to create an ideal setting for your new arrivals. Gradual exposure and hardening off is key. Tissue culture plants require time to adjust to their new surroundings.

Slowly introduce your tissue culture plants to the light and environmental conditions they’ll encounter during their growth cycle. Be sure to keep them in plenty of humidity and monitor your plants diligently during the acclimation process. Keep a watchful eye for signs of stress or nutrient deficiencies, providing the necessary support as needed. Integration marks the culmination of the acclimation journey. Once your tissue culture plants have successfully adapted, they’re ready to join your primary grow area. Continued monitoring ensures their ongoing health and vitality.

Schedule: A Step-by-Step Tissue Culture Timeline

Initiation Phase: Weeks 1-4

-

- Weeks 1-2: Sterilize the tissue culture plants and introduce into the culture medium

-

- Weeks 3-4: Establish the tissue culture plants, free of contamination

Multiplication Phase: Weeks 2-8

-

- Weeks 1-4: Remove healthy shoot growth from explants and subculture (transfer into fresh medium) to multiply the stock

-

- Weeks 5-8: Continue to subculture tissue culture plants to increase the number of shoots. Duration can vary based on desired multiplication and growth rate of specific cannabis strains.

Rooting Phase: (~4 weeks)

-

- The plantlet is transferred to a new medium containing auxins that promote root formation. Alternatively, a tissue culture plant can be transferred directly into a rock wool cube or preferred substrate to develop its root system.

Acclimation Process: (~4 weeks)

-

- Slowly introduce the plantlets to the outside world, similar to the method for hardening off a regular clone. Gradually increase light intensity and adjustment to its environment.

And for a final (and potentially simpler) option, you can simply source acclimatized and tested tissue culture clones through a trusted tissue culture and genetics expert like Next Big Crop. This process is very similar to sourcing traditional clones or cuttings.

These tissue culture plants will be rooted, hardened off and ready for transplant immediately upon arrival at your facility. Reach out to Next Big Crop today for all of your tissue culture needs, including: tissue culture laboratory design and equipment, tissue culture standard operating procedures and training, genetic restoration, storage and sourcing.