By Aaron Mullins – Systems Coordinator, NBC

With the COVID-19 pandemic creating uncertainty surrounding the cannabis cultivation workforce, automating your grow room systems is increasingly a necessity rather than a luxury.

While it can be a costly endeavor on the front end, investing in automated cannabis cultivation systems ensures your marijuana plants are consistently getting the water, nutrients and light they need, even if there aren’t employees onsite to give it to them. But that’s not where the benefits end.

Even if there weren’t a pandemic affecting the cannabis cultivation workforce, a fully human-powered operation is not a sustainable or competitive model, so implementing the right automated systems is almost always a good investment.

Here are the top 5 cultivation facility systems worth automating:

1. Irrigation systems and nutrient dispersal:

Automated irrigation systems are an incredibly valuable tool for commercial cannabis cultivators. Automated irrigation systems can help cultivators manage their operations remotely in the event they can’t be on site or there is a staffing shortage—something all cultivators must take into consideration during the ongoing coronavirus pandemic.

An automated irrigation system additionally ensures your plants are fed on schedule with a consistently measured and mixed blend of nutrients.

Such systems aren’t cheap, but they’re worth it. Top-of-the-line systems cost between $20,000 and $50,000 for a 20,000-square-foot facility, and they typically pay for themselves in six months to a year. For a larger facility, the payback time can be less than three months.

Automated irrigation systems further reduce a cultivator’s reliance on human labor by mixing nutrients via quick digital input capabilities. This type of system also can test the nutrient levels before and after the mixing process.

2. Lighting systems:

In a large commercial grow, automated lighting systems are an invaluable productivity tool. With such systems in place, growers can remotely adjust light spectrum and intensity, improving plant growth and lowering electricity bills.

If you’re growing cannabis indoors year-round, the health of your crops is at the mercy of your lighting system—so you’ll want to make sure it’s a good one. The best systems allow you to quickly identify undesirable environmental changes in your grow facility, and also enable remote correction capabilities (typically through a digital app), saving time, labor and resources.

Lighting automation systems are, without a doubt, worth the up-front costs for large-scale commercial growers. But be sure to select a manufacturer with a good reputation and a system that offers a diverse range of controls.

3. Environmental controls:

There are a number of environmental factors beyond lighting that can be automated to improve cultivation operations. Temperature, relative humidity, CO2 concentration, vapor pressure deficit and soil moisture all play a role in the quality of your crop.

Large-scale cultivators I work with often opt to utilize advanced environmental control systems that are customized to automate all of the necessary environmental systems within their facility. Beyond the convenience and labor-saving benefits of such systems, the ability to eliminate human error and precisely control environmental variables within a facility is key to efficiently producing high-quality flower at scale.

4. Trimming systems:

If you’re growing cannabis at commercial scale, you’ll want to invest in a marijuana trimming machine. Unless you’re a craft grower selling your flower at premium prices, hand trimming just doesn’t make sense for your bottom line.

Old school cannabis connoisseurs are sometimes critical of machine-trimmed marijuana, but the vast majority of consumers cannot tell the difference between hand-trimmed flower and machine-trimmed flower. Thanks to rapid industry growth, trimming technology has improved leaps and bounds from where it was just a few years ago.

From expediting the trimming process to sorting and separating buds by size, trimming machines can improve efficiencies around a number of tedious, time-consuming tasks post harvest.

5. Data collection:

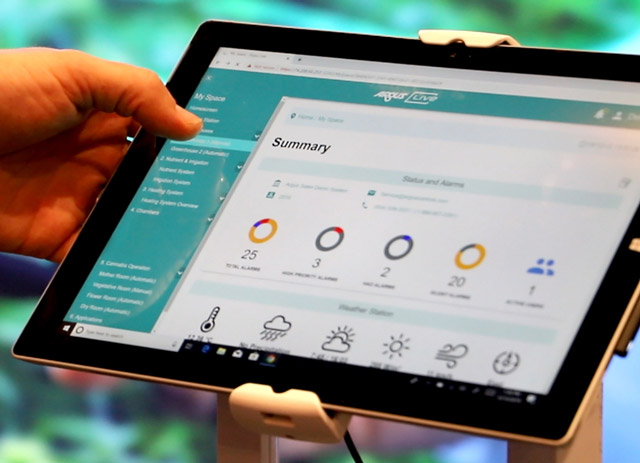

If you’ve automated most of your cannabis cultivation systems, you’ll receive the added benefit of automated cultivation data collection—an integral aspect of any sophisticated cultivation facility. Automatic and precise data collection enables cultivators to monitor and control their inputs, outputs and results, leading to more consistent yield, higher-quality output and improved processes.

Tracking metrics around temperature, relative humidity, CO2 concentration, light, vapor pressure deficit and water content in the growing media helps growers determine what works best in their facilities, and enables them to dial in the optimal growth conditions for optimal results.