By Brendan Bartolo, Construction Project Manager – Next Big Crop

After you’ve completed the design phase of your marijuana cultivation facility, it’s time to select finishes.

Your marijuana cultivation operation’s size, location and layout will somewhat dictate what finish materials will work best. And of course, price also will be a major consideration when selecting finishes.

Pro tip: Prioritize what you need to complete to get your business up and running. You can save money on the front end by finishing less-important areas of the building after you have cash flow.

You need to have your critical cultivation spaces finished to begin operating, but you can get away with finishing the front-of-house space and the office areas later. There also may be aspects of the building, such as ceilings, that don’t need finishing at all.

And as you’re assessing your needs, take a step back and look at the big picture. There are lots of areas where you can, and should, trim fat. In general, you should always be on the lookout for price gouging and upselling.

But your choices shouldn’t be based on cost alone. Major considerations include durability of materials, creating a space that’s easy to work in, and ensuring the grow areas are easy to clean, safe and code compliant.

Top-to-Bottom Marijuana Cultivation Facility Finishes

The areas where finishes matter most are the walls, floors and the building’s insulation.

Ceiling

Consider whether you need to finish your entire ceiling. If it’s in an area that doesn’t require it to be finished, you can save a lot of money by leaving it exposed.

Walls

Selecting the right finish for your walls when you’re building your grow room is important because the environment in marijuana cultivation facilities can be so warm and humid—when plants reach full size, it’s a jungle in there.

For indoor facilities, we recommend using walling made of fiber-reinforced plastic (FRP) because it’s visually appealing and plenty durable—you can spray down FRP walling with a pressure washer, which makes for more speedy and convenient maintenance.

Keeping the environment clean is also a critical factor for preventing outbreaks of pests and plant diseases, so every facility should have a spray-down-and-clean area. If your plants will be on tight racks, the space they’re in should be waterproof.

Dehumidifier System

You’re growing products for human consumption that will be lab-tested for safety, so it’s important that walls are easy to clean and water-resistant to reduce the risk of pathogen growth. Investing in proper marijuana growing equipment such as an appropriately-sized dehumidifier system is worth the money for cultivators operating at any scale.

Floors

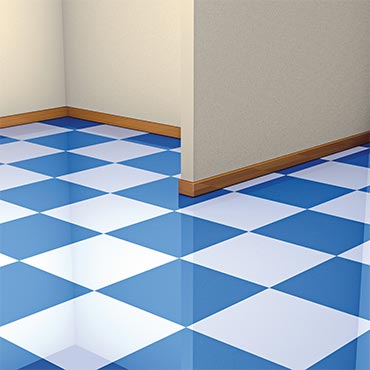

For floors, we recommend vinyl composite tile (VCT) or grinding and sealing concrete rather than applying extensive epoxy.

Contractors often recommend epoxy floors because it has a higher profit margin than other materials, but it can be slippery—especially when it’s wet—and sometimes doesn’t bind well to existing flooring in older facilities, which makes it a safety hazard.

Insulation

Installing a VCT floor or grinding concrete and sealing it with a light broom finish is more cost effective, safe and better all around than epoxy.

Insulating the building is especially critical to minimize chances of moisture in the air condensing and forming water droplets on the wall, which would be a breeding ground for mold and mildew.

Roof

You can also insulate the roof in existing structures. If it’s an older building, it can be insulated from the outside by using a cost-effective thermal plastic overlay.

Due Diligence is Necessary in Choosing a Contractor

Safety and compliance are the other guiding factors for finishing needs. This is also an area where you’re vulnerable to a lot of upselling, so keep that at the top of your mind.

Assess your facility design and identify any areas where you could expose employees to potential hazards, but watch out for contractors who will try to squeeze more money out of you by pointing to jargon-filled code compliance PDF documents that have a lot of fine print.

They may recommend larger spaces than you need for certain functions, or more expensive materials and equipment, so be sure to do your own research so you have an understanding of what the codes are, or hire a knowledgeable consultant to work with contractors on your behalf to get the best deals while ensuring you stay compliant.

You should also get bids from at least three different contractors before deciding on one. It’s easy to get taken advantage of without the right people working by your side.

Learn more about Next Big Crop’s facility design consulting services here.