Facility Design

The New Cultivation Facility Design Experience

Raising the Bar in Cannabis Cultivation Design

Cannabis cultivation facility design is a lot like planting a seed; you’ll need the right consultants to help your business and facility grow.

So, you’ve overcome the obstacles of procuring a license; now what

Getting started in the cannabis industry can be incredibly challenging. Not only are there confusing laws and regulations, but there are also plenty of potentially disastrous pitfalls you can encounter along the way.

You’re probably somewhat familiar with the methods and the equipment required of a functioning commercial grow room. Still, when it comes to a cannabis cultivation facility’s actual design, you might be out of your league. The differences between growing cannabis at scale and growing cannabis in a backyard garden are vast.

Success in the cannabis industry requires long-term vision, and it can be a costly gamble if your grow room design isn’t up to snuff.

In the early planning stages, too often, industry newcomers make big mistakes. And the long-term implications of their mistakes can be catastrophic since this critical part of the process requires extreme precision.

There are many factors to consider, and careful planning that includes a smart layout and close attention to environmental, infrastructure, and compliance concerns is crucial.

What Makes a Good Cultivation Facility Design?

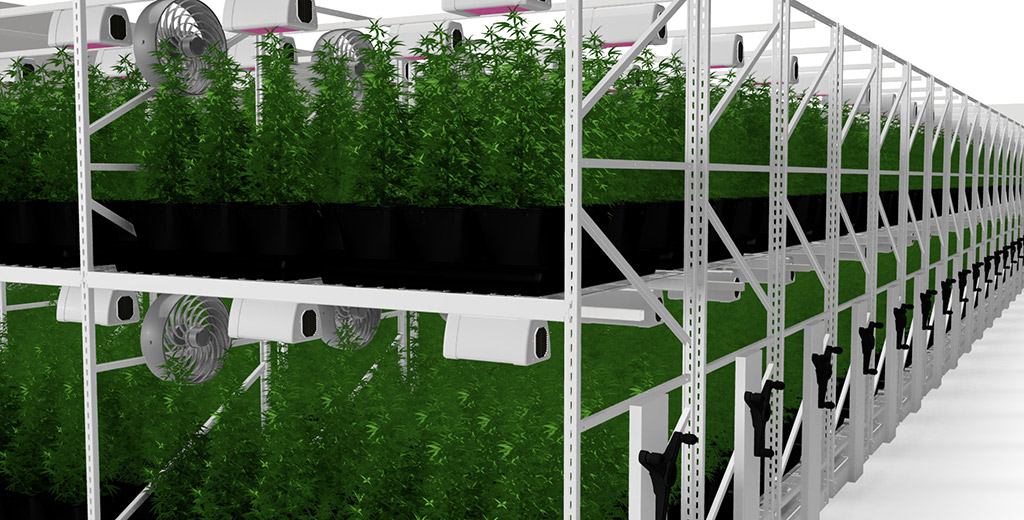

Good cultivation facility design creates a workflow that maximizes efficiency and minimizes contamination. And in a post-pandemic world, efficient workflows are a more significant concern. Limiting the number of people in the facility by investing in automated irrigation systems, lighting, trimming equipment, and environmental control systems can keep your facility clean and prevents contamination.

When it comes to indoor plant cultivation, there are crucial details you should never overlook. These details include flooring (we recommend affordable solutions like vinyl composite tile or grinding), walling (fiber-reinforced plastic), and an appropriately sized dehumidifier system.

You’d be shocked at how many people attempt to cut corners when it comes to an HVAC system. Investing in a proper HVAC system prevents contamination and costly mistakes. If you don’t make this investment, you might watch your crops and profits go up in flames.

Unless you’re well-financed, you’ll likely be the project manager responsible for the grow room setup and design. And even though you have a great vision, you probably have a modest budget.

Know this: a cheap initial design often becomes a more expensive problem down the road.

Your facility design can make or break your business – working with the right cannabis consultants isn’t a recommendation – it’s a business requirement.

We’ll help your cannabusiness grow.

We have decades of collective experience in designing commercial cultivation facilities and dispensaries. And we use our expertise to enhance our client’s vision and create a streamlined and efficient grow room design and space plan.

Utilizing the best horticultural systems and technology, our designers work with local architects and engineers to maintain focus on process flow management, space utilization, and compliance through the design and permitting phase.

Once you’re operational, we help develop a commercial cultivation business plan and partner with you to train your staff on the site’s operation and maintenance, ultimately transforming your team into experts.

Our Cultivation Facility Design Services Include:

- Conceptual Layouts

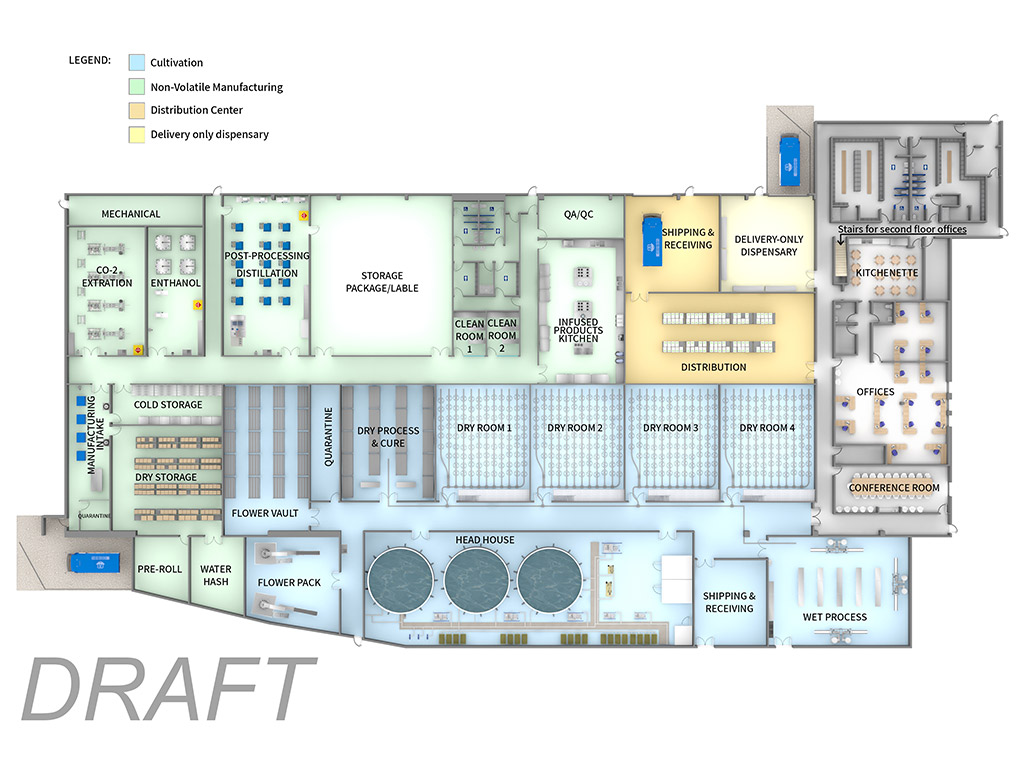

NBC can provide flexible facility programming and design. We have expertise in all aspects of cannabis production, from cultivation to extraction, processing to retail.

- Floor Plans

NBC’s design team will optimize your facility based on existing conditions to ensure the most efficient space use.

- Site Plans

We will keep state regulations in mind when designing your facility to maintain compliance, and we’ll create a plan that factors in expansion and ease-of-use.

- Lighting

Our team has extensive experience with all types of grow light systems as well as lighting control. We work directly with lighting manufacturers and can provide the best system for your facility.

- Security and Surveillance: Plans & Systems

Our design team uses their in-depth understanding of State regulations to develop security systems that meet or exceed compliance requirements.

- 3D Renderings

NBC utilizes state of the art building modeling software to illustrate our designs. We can also develop 2D and 3D models for client review and analysis.

- Utility Efficiency Analysis

Our design parameters include systems that contribute to sustainability and energy use awareness. Our building management systems provide real-time energy and resource reports for analysis.

- Equipment Specifications and Layout

NBC has purchasing relationships with many agricultural and cannabis equipment suppliers. We only recommend equipment that we’ve personally observed and that we know can provide measurable value.

- Design Review

The design development process features multiple peer review sessions to ensure that your project is on track and built to the known specifications.

- Construction Permitting Support

NBC works closely with our architectural partners and local municipalities to ensure the design is complete and approved on the first submittal.

FAQ

Next Big Crop is a full-service cannabis consulting firm. We can improve your cannabis business outcomes at every development stage – whether you’re just starting or you’ve been in the game for years.

We can assist with license procurement, facility design and construction, systems integrations, equipment, materials sourcing, management, compliance, and more.

You must develop a business plan, determine your budget, and secure funding before completing a license application. Most importantly, you’ll need to research your state’s cannabis laws and license application requirements.

We understand that learning the industry can be a daunting task, so we offer license procurement services.

With our comprehensive knowledge of the cannabis industry application process, we have won and secured operational licenses in competitive markets from PA, MD, OH, CO, AK, VA, CA, and NV.

Understanding how to analyze commercial cannabis production costs will give you insight into your potential production costs. We wrote a comprehensive blog on the topic you can find here.

Having a lead master grower with intimate knowledge of the different types of finished cannabis is incredibly beneficial, but finding this cannabis guru can be difficult.

When hiring a master grower, or cultivation manager, you must ensure the grower is equipped to run your cannabis business. We put together a blog to help you determine whether or not a master grower can handle essential business operations. You can read the piece here.

Upgrading your cultivation facility is almost always the intent for most people starting a cultivation business on a minimal budget. But scaling your operations is expensive.

You should ask yourself one thing before attempting to scale: will an upgrade investment increase profitability and productivity?

If the answer is “yes,” you will need to determine a budget, have a well-thought-out plan and strategy.

Once you have completed your cultivation facility design, you’ll need to select the appropriate finishes. Your selected finishes will be based on different factors like grow op size, location, and layout, along with your budget.

Limiting the number of people in your facility keeps the environment clean and prevents contamination.

Typically, a facility requires staff with a unique skillset (cultivation managers, master growers, junior growers), but more owners realize they can save dollars by automating specific processes like watering, trimming, and environmental control. Process automation has also proven beneficial when staffing becomes a challenge, as we’ve seen during the coronavirus pandemic.

Your cultivation methodology and plant count will generally dictate how much space you need to achieve optimal output at your facility. You can learn more about the process here.

There are many variables to consider when determining a dehumidifying system, like room temperature, plant quantity, and watering schedule.

You can figure one ton of cooling for every two high-pressure sodium (HPS) grow lights or four LED lights. Here’s your mantra: water in equals water out.

When plants start growing, it can become warm, dense, and humid like a rainforest, which is why it’s essential to understand the importance of dehumidifying and to invest in a good dehumidifier or HVAC system.