By Christian Phelps, Operations Director – Next Big Crop

If you want to know how well your cannabis cultivation facility is performing, measuring your harvest yields in a few different ways can help to tell the story.

Calculating yield metrics is traditionally used to estimate revenue, but it’s also important to understand the relationship between yield and overhead costs. Here’s a quick breakdown on how to measure cultivation yields and positively influence your business.

Why Wet Yield Weight Matters

It’s a smart plan to track both the wet yield, right after the plants are harvested, in addition to the final dry weight post-processing as part of key cultivation data to collect when figuring out how to optimize your facility’s output.

The dry weight is ultimately the most important piece of the puzzle because that’s what you’re selling, and this is the standard metric for assessing facility productivity. That said, don’t discount the value of knowing the wet-yield of each strain as you complete each production cycle. Wet yields will allow you to benchmark and immediately assess your most recent performance against previous production cycles.

Measuring wet yield has another key benefit: It helps your sales team understand how much product is available to pre-sell to your buyers.

For example: If your harvest of Original Glue is 400 pounds wet yield, roughly 20% to 25% will translate to salable dry product, or about 100 pounds (the exact ratio varies by strain and will also be influenced by your packaging team’s preferred moisture content). That knowledge will empower your sales team to let dispensary buyers know how much Original Glue will be available well ahead of the curing and processing time. If they can presell 80 percent of your harvest, it will be ready to ship out as soon as it’s packaged, optimizing your turnaround time and providing access to the freshest products available for your consumers.

Cannabis Yield Per Square Foot and Other Metrics

There are several ways to calculate facility productivity based on the dry yield, including but not limited to:

- Grams per square foot of canopy

- Grams per watt of light

- Grams per kilowatt (kWh) hour

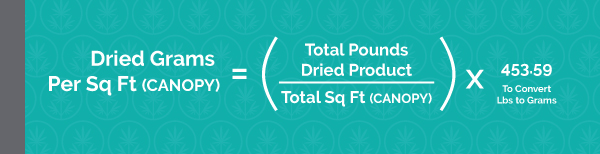

In my opinion, the most important yield measurement to track is grams of dried cannabis per square foot of canopy. To calculate yield in this manner, divide the total number of pounds of dried product by the square footage of canopy, then convert to grams. This method provides a “quick and easy” calculation of your productivity based on the facility’s footprint and will allow you to compare the performance of different strains or harvests easily, since the size of your canopy will remain constant.

Cannabis Yield Per Square Foot Formula

Factoring in Energy Usage

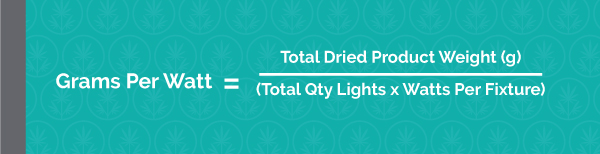

Another metric some cultivators rely on is grams per watt of light. To calculate yield in this manner, divide your total dried product weight by total lamp wattage. Like grams per square foot, this method allows you to benchmark your performance based on a constant, since it is unrealistic to assume that you are regularly changing the number of lights, or type of light in your flowering space. Using grams per watt becomes more useful if you are evaluating multiple types of lights, or if electricity is expensive in your area, and you are working toward achieving higher yields with lower electricity requirements.

Grams Per Watt Formula

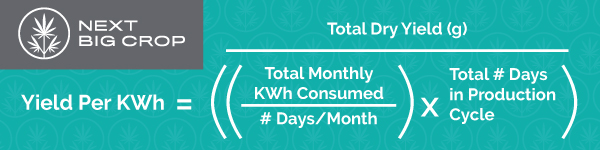

Calculating your grams of dried product per kilowatt hour (kWh) takes the grams per watt measurement a step further. By incorporating all of the other systems that rely on electricity, you are able to understand the relationship between total utility consumption and harvest yield. Large variances in yield per kWh will tell you if your systems were run more efficiently from one harvest to the next, and help to identify environmental issues that may be influencing your total facility output. Are your environmental systems working harder than they should be (or not at all)? Perhaps you operate in a greenhouse and had a cloudier-than-normal period that required you to run your lights more often. Tracking yields this way will help you to identify if there are external factors influencing your energy usage, and ultimately your bottom line.

Calculating Yield Per kWh

To calculate yield per kWh, you will need to understand your average daily energy consumption. Pouring over utility bills is helpful, and having historical information to draw from will only improve this analysis. First, you will multiply your average daily kWh consumption by the number of days required for that production batch to understand your total kWh consumption for that harvest. Next, you will take the total dry yield (in grams) and divide it by the total kWh of energy consumed, to arrive at grams per kWh.

Yield Per kWh Formula

Regardless of which method you choose, benchmarking your performance each harvest will provide worthwhile data points that allow you to make micro-adjustments and steer your business toward increasing yields and revenue.

Taking this a step further, businesses have the ability to use this yield information to benchmark their internal performance from a cost perspective. We spoke about factoring in energy consumption, but what about labor, grow media, nutrients, water, rent, etc.? Ultimately, you want to produce at the lowest cost, and sell at the highest price to maximize your profitability. By understanding the relationship between costs and yield, we can hone in on our cost per pound or gram. The larger the difference between what you sell that pound/gram for and what it costs you to produce, the more profitable your operation is.

It’s easy to get into the weeds (pun intended) with all of this data, and it can sometimes be overwhelming—analyzing income statements, labor hours, energy consumption rates and cultivation yield data, to name a few. You don’t have to jump right into the deep end, but the stronger your understanding is of your business operations, the better and more informed your decisions will be.

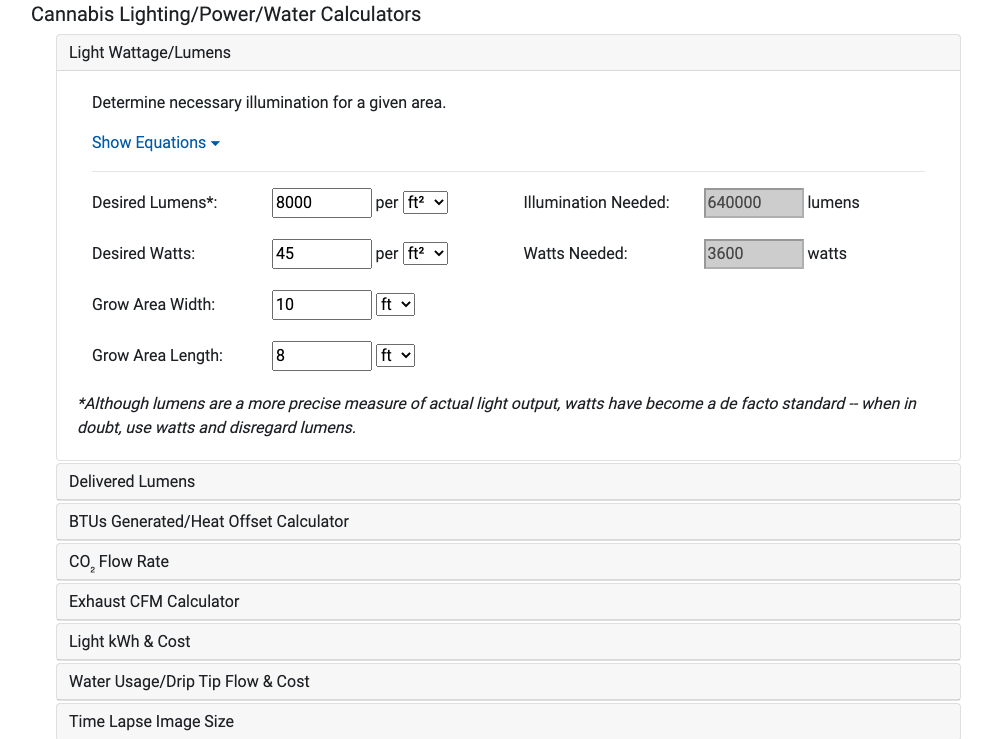

If you’re not a math whiz, there are many calculators out there that let you plug in the values for whatever it is you’re looking for. Canna-calc.com has calculators for everything from water usage to lighting intensity, while the State of Oregon provides a calculator for doing rough kWh estimating.

Learn more about Next Big Crop’s facility management services.