You’re not still mixing nutrients and watering by hand, are you? If you’re still manually irrigating your cannabis garden, this blog is for you. And even if you have some portion of your irrigation process automated but are looking for ways to decrease labor and increase yields and overall efficiency, pay attention. Automating your entire nutrient delivery system may be much simpler and more cost-effective than you might guess.

We’ve written before about why hand-watering cannabis plants is a bad strategy, even if you’re running a small two-light operation. While some old heads will always stick to what they know, being forever tied to the garden is no way to do business. For just a couple thousand dollars—or roughly the yield you can get from 2-4 cannabis plants—you can drastically reduce the time and human resource expenditures hand-watering requires, not to mention trim utility expenditures.

Regardless of facility design trends, commercial cannabis cultivation comes down to two main factors: yield and efficiency. And it’s really, really hard to maximize both without automation. There are all kinds of ways to integrate dosing into the garden depending on your cannabis facility design choices. But one of our favorite companies to work with is Dilution Solutions, the makers of Dosatron and the industry leader in fertilizer injection and delivery.

To get the wheels turning for hand-waterers and semi-automated growers alike, we sat down with Dosatrons’s own Wally Behnfield, who heads up technical sales, working with growers to specify the right setup for their specific applications.

Irrigation Dosing Systems for Commercial Cannabis Cultivation

Wally also happens to be a long-time buddy of ours here at Next Big Crop, and our go-to person on the in

side over at Dosatron. We asked Wally to show us the most common and versatile setups he sees every day in the field, and to give

Dilution Solutions/Dosatron users some tips and tricks to get the most out of their setup. Here’s what he had to say:

“Every grower and facility is unique, so every system ends up being semi-custom. It’s up to the grower, along with an experienced design team, to specify the right combination of dosers, filters and sensors to achieve the grower’s irrigation goals,” said Wally. “Designing the dosing system is just one piece of the puzzle. You’ll also need to take into consideration the water treatment and storage, and the delivery of the mixed nutrients throughout your rooms and onto your benches.”

Wally’s top tips for accurate cannabis fertigation and irrigation:

- Consistency. The best growers keep it simple and consistent. Consistency is more important than almost any other factor—which is why cultivation systems automation and drip irrigation are key to a successful grow

- Filters are your friend. Wally especially likes Arkal or Amiad-brand disc filters

- A little housekeeping goes a long way. All filters should be cleaned 1-2 times per week. Clean your irrigation lines regularly, too, with hypochlorous acid at 1-2 mililiters per gallon

- Tape vs putty. When installing your system integration components use Teflon tape, not putty

- Perform in-field maintenance. Use rebuild kits every 6-12 months—depending on the frequency of use—to extend the life of your Dosatrons on-site without sending in your injectors for service

As you can see, maintenance is key to getting the most out of your irrigation system design. Your required maintenance cadence and approach will depend a lot on your water quality and the fertilizer products you choose to use. Fertilizers containing organic material can very quickly clog emitters and encourage the buildup of biofilm in your irrigation lines. Organic growers especially need to take cleanliness and maintenance very seriously.

The more filters you include in your irrigation and fertigation system the better. Be sure to include a prefilter that catches particulate matter in your water input before it reaches the Dosatron setup. Additional filters on the delivery side will keep your injectors running smoothly and your emitters free from clogs, too.

The Power of a Piping and Instrumentation Diagram (P&ID)

A Piping and Instrumentation Diagram (P&ID) can be extremely helpful for growers who want to follow Wally’s advice. A P&ID like the ones produced by Next Big Crop provides operators and installers with all the information they will need to install the fertigation system, including detailed schematics laying out all process piping for the system. Putting together a well-thought-out and detailed design is crucial for accurate and trouble-free irrigation.

In Wally’s experience (and ours as well), the best growers in the game keep it simple when it comes to their irrigation. As growers gain experience and dial it in, they tend to drop the fancy additives and get back to basics. A simple two-part fertilizer, with one additive at a time is the most common setup for top-tier growers, he says. In this scenario, the additive can be rooting stimulant, silica during the vegetative phase, or your fertilizer brand’s recommended bloom enhancer during the flowering period.

Fertilizer cost is also a big consideration for fertigation automation. In constantly tightening markets, keeping a close eye on your fertilizer costs can make a big impact on your bottom line. How much you pay for a gallon or pound of your favorite fertilizer is less important than your all-in cost per feed gallon. Cost per feed gallon is the number you want to be tracking.

The most cost-effective growers are landing somewhere around 3 to 5 cents per feed gallon—all in. We’ve seen growers with numerous fertilizer parts and heavy hands come out 5-10X times that cost. This is another reason why consistent and accurate fertilizer dosing is key and can pay for itself very quickly.

Three Dosatron Irrigation Designs for Commercial Cannabis Cultivation

Here are 3 examples of our favorite Dosatron setups along with some explanation:

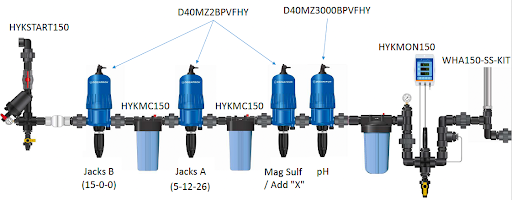

1. 4-Part Greenhouse System (HI-FLO)

The D40MZ Series injectors are great for Greenhouse and Outdoor applications, allowing for water flow rates up to 40 Gallons per Minute. This example is designed to deliver a 3-part fertilizer recipe along with a pH adjustment solution.

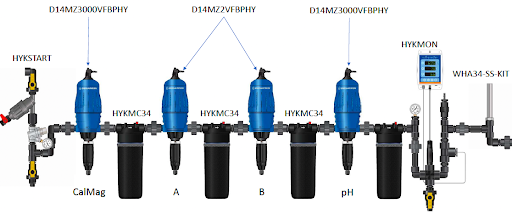

2. 4-Part Indoor System (LO-FLO)

The D14 injectors operate between 2-10 Gallons per minute to fit smaller applications. This example is designed to deliver a 2-part fertilizer recipe, along with CalMag and a pH Adjustment solution

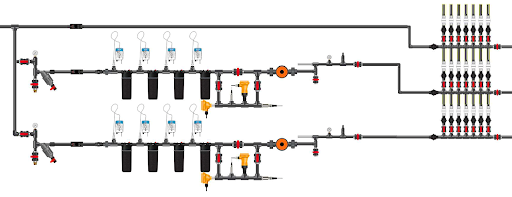

3. Etatron Systems (x2) with Controller

The Etatron System paired with the Dilution Solutions Controller is perfect for the grower that wants full control of their Irrigation & Fertigation systems and an easy platform for operation. These systems are designed to fit each growers custom recipe, and can accommodate more than 15 nutrient solutions when needed. This example is designed to deliver separate 3-part Flower and Veg Recipes along with pH Control, allowing for direct feeding to the irrigation system or filling of batch tanks with blended recipes.

How does your facility stack up? If you aren’t hitting target canopy numbers, reach out today for a cannabis facility design review.