By Chris Lundgren, Sales Director for Dosatron

Growing really good weed just isn’t enough to carry a cultivation business these days. You also need accurate production forecasts to meet revenue targets and budgeting for expansion.

So I have to ask: In this day and age of ultra-competitive markets and pandemic staffing challenges, why are hand-mixing nutrients and hand watering even a thing still? Plus, a common complaint in cannabis cultivation is that there are too many cooks in the kitchen, with employees going their own way and sometimes cutting corners.

Regardless of the size of your grow—whether you have a boutique greenhouse that focuses on craft cannabis, or you’re growing tens of thousands of plants per production batch—your schedule for watering and feeding (aka fertigation) needs to be consistent, and automation is what gets you there. That’s all there is to it.

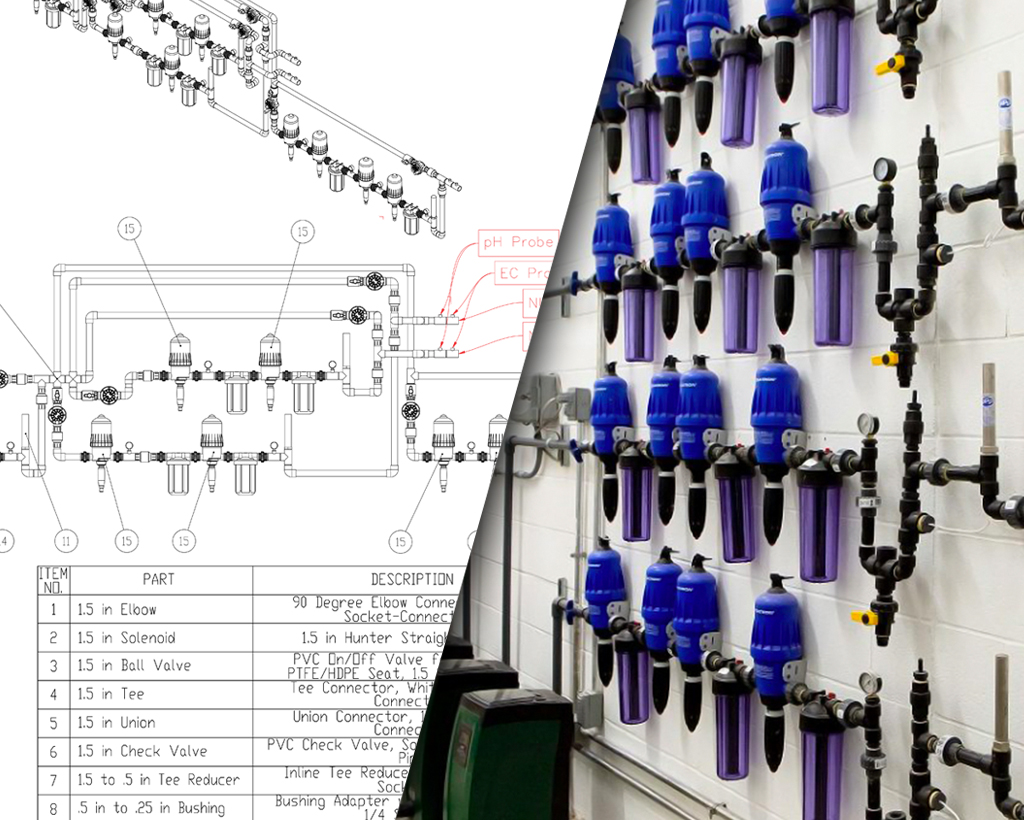

Cannabis nutrient delivery systems can seem complex, no doubt, with lots of monitors and sensors and programming to tackle. But don’t be intimidated. They can also be simple yet effective, and intuitive in their functionality. That’s precisely what Dosatron is all about. And this is a prime reason why Next Big Crop chooses to work with our team at Dosatron for systems integration in all types of cannabis cultivation facilities.

We also have deep experience serving a wide range of industries over the past 30-plus years: crop production, animal agriculture, car washes, sanitation, printing, water treatment, food safety—we’ve dialed in the best way to deliver consistent results, day in and day out.

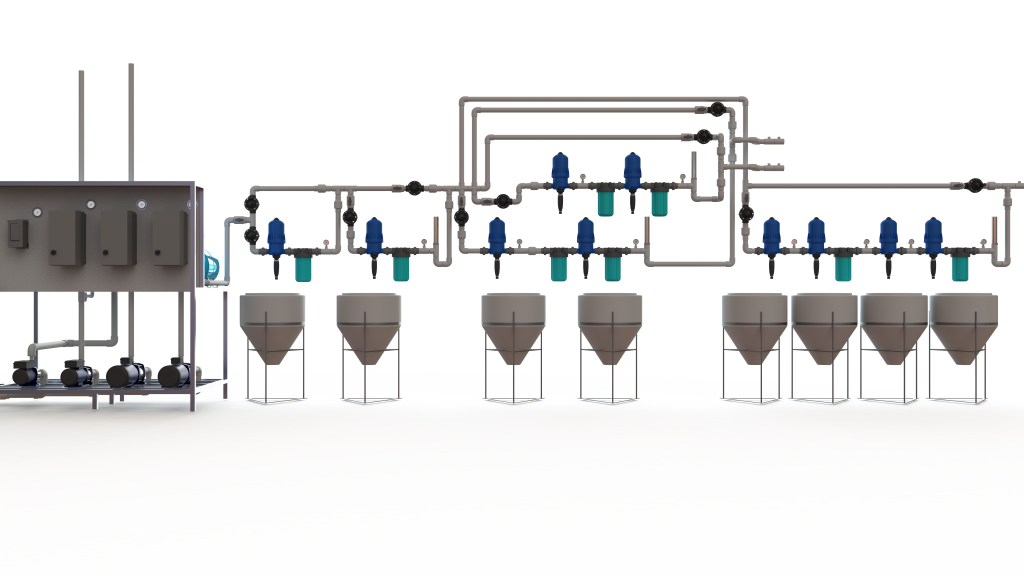

Let’s take a peek inside the Dosatron system:

How the Dosatron Nutrient Delivery System Works

At its heart, the Dosatron is a water-powered volumetric dosing device that’s designed to be simple, reliable and always repeatable. Growers can depend on it because it’s based on setting a doser to a specific dilution rate.

The mechanics are simple and don’t require electricity: As water passes through the Dosatron device, it moves an internal motor, which draws up the additive to be diluted from the stock tank (similar to a hypodermic needle, except in this case it’s mechanically drawing up the substance via water motion). It mixes water with the substance, be it fertilizer, pH additive or other nutrients, then emits the precision-blended solution.

Dosatron is the only inline fertigation system designed to be completely volumetric. This means the mixing of the solution is proportional based on the volume of water as it increases or decreases—there won’t be any variation in the water-to-product ratio.

Here’s an example: For 5ml of additive per gallon of water, the Dosatron can adjust from 1 gallon per minute to 10 gallons per minute based on flow volume; it maintains that proportional volume of 5ml of additive per gallon, no matter what.

When multiple Dosatron units are configured into a series, it becomes a full-fledged Dosatron Nutrient Delivery System (NDS). This gives us the ability to implement a customized, modular approach—one that’s flexible to a grower’s methodology and the different types of nutrients that are applied at various phases of the growth cycle.

Configuration Options Design for Scalability

The Dosatron NDS is a scalable system designed to work for all cultivators, from mom-and-pop sized operations to large-scale commercial facilities. It’s effective for both soil and hydroponic growing styles and can be easily configured for indoor, greenhouse and outdoor operations.

Our goal is to meet each customer where their current needs are, with an eye on the future. Thanks to the modular Dosatron setup, it’s customizable and adaptable to cannabis facility expansion. It can also be integrated with third-party sensors and monitors for data collection.

Simply based on the irrigation water demand (flow rate) and the target application rates of the products being dosed, the Dosatron can easily be implemented into most existing plumbing infrastructures, offering multiple options ranging from low-flow to mega-flow fertigation systems.

Serving Clients With a Customized Approach

As I’ve said before, there are some pretty complicated cannabis nutrient delivery systems out there, and some take a very regimented approach, with limited options for configuring.

But there’s a lot of nuance to growing cannabis, and growers shouldn’t be pigeon-holed into a fertigation program based on their equipment alone.

This is where working with a highly skilled design team such as Next Big Crop makes a difference in getting exactly what you want out of your cultivation setup.

Next Big Crop’s experienced staff is well-versed in facility design objectives and optimizing facilities for production. They get the groundwork laid out just right, with their knowledge of ideal flow rates for any size facility, and their expertise configuring the NDS based on individual grower’s preferred nutrient “recipes.” Together, Next Big Crop and Dosatron representatives go through the variables and dial it in for each grower’s objectives.

Likewise, as a facility’s needs change, we’re all here to help. If a new cultivation manager comes in and wants to use a different nutrient formulation, we’d work with the grower to adapt the Dosatron setup for the new methodology. And we’re always available to provide education, troubleshooting support and share tricks of the trade.

I appreciate the way the Next Big Crop staff bring specialized knowledge to the table, from being well-versed in construction and building infrastructure, to the workflow within a facility, to the operational details; they serve as a one-stop-shop for getting a facility operating at maximum efficiency—always with an eye on scaling.

Plus, they’re great people who believe in what they’re doing. At Dosatron, we couldn’t ask for a better partner in the cannabis cultivation space.

Are you looking to take your cultivation fertigation to the next level? Learn more about Next Big Crop’s systems integration services.