10 Reasons Why a “Master Grower” is Unequipped to Run Your Cannabis Business

Bringing a fake-it-til-you-make-it mentality into commercial cannabis cultivation is setting yourself up for failure.

Bringing a fake-it-til-you-make-it mentality into commercial cannabis cultivation is setting yourself up for failure.

Understanding ROI for grow op scaling: Before you drop serious coin on upgrades, there’s a few things to know about scalable cannabis business.

Collecting cannabis cultivation data helps growers achieve bigger and more consistent yields. Get intel about weed metrics and cannabis production measurements.

Efficient cannabis harvesting is essential for modern cultivators. Here’s how the pros establish optimal commercial cannabis harvesting efficiency.

Marijuana cultivation facility finishes: Depending on your cultivation facility’s size, location and layout, some finish materials are much more cost-effective than others.

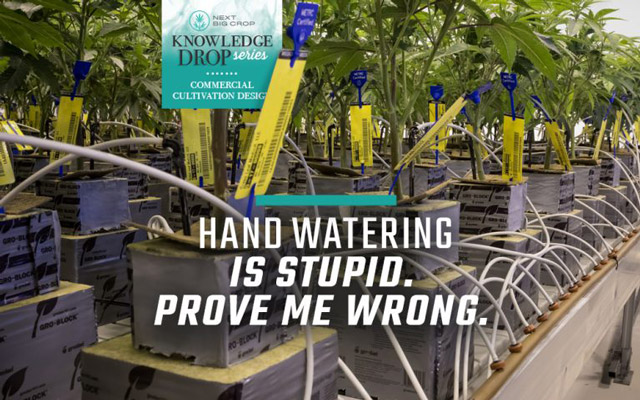

For today’s cannabis cultivators, irrigation systems for cultivation facilities provide massive labor savings and peace of mind that crops will be consistent.

There are plenty of marijuana trimming machines available for commercial cannabis cultivators today. But debate still rages about how to trim weed at scale.

To reduce labor costs for cannabis cultivation, automation for irrigation, harvest and environmental control benefits facility owners and their employees.

Your grow room setup defines your workflow and the volume of cannabis plants you can grow per cycle, so it’s critical to know how much veg space you need.

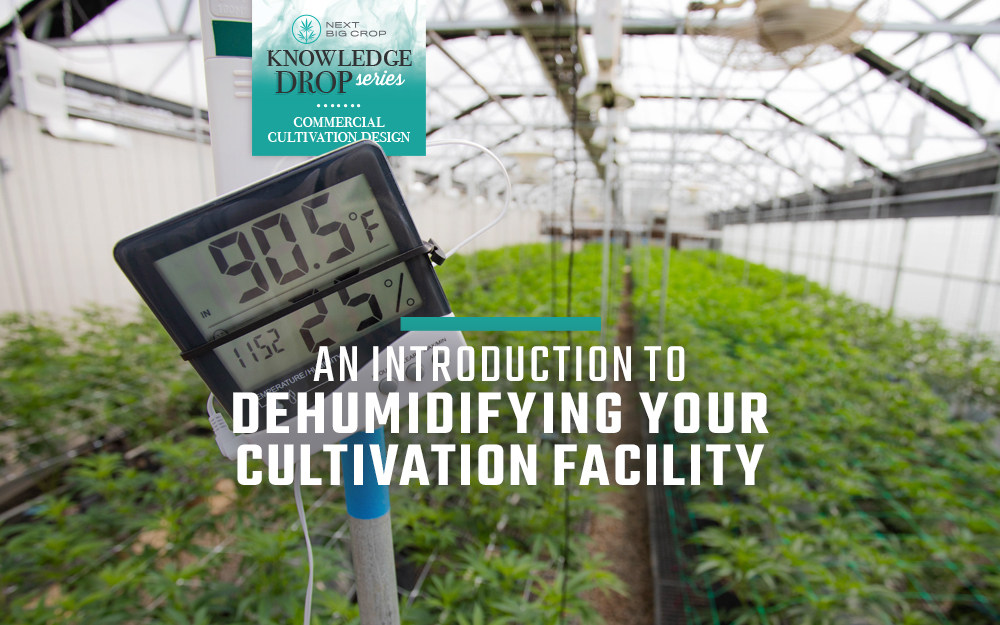

Investing in a proper grow facility dehumidifier system and finding the right engineer to handle the project takes considerable resources, time and effort – but it’s well worth it for commercial cultivators of any size.